All these Yellowstone glitching mysteries may finally be headed for a conclusion. It looks like there are at least two separate problems with different causes: one causing glitching during a bus cycle and the other causing glitching at the end of a bus cycle.

Fighting at End of Bus Cycles?

This one is complicated to explain, so bear with me. You should understand that the Apple IIgs is a 5V system, but Yellowstone uses a 3.3V 74LVC245 to communicate on the data bus. This works because the LVC family is 5V tolerant on its inputs, and its 3.3V output is high enough to be sensed as a valid “high” by 5V logic chips. On the IIgs motherboard there’s a 74HCT245 that handles the computer’s side of transfers to and from the data bus.

Yesterday I noticed something curious: when Yellowstone is driving a 3.3V high value onto the data bus, at the end of the bus cycle the voltage always immediately jumps up to 5V, and stays there for a few hundred nanoseconds until something else puts a value on the pus. What’s doing that? Is there a 5V pull-up resistor on the bus, or something similar? No. When Yellowstone is driving a 0V low value onto the data bus, the voltage remains at 0V after the end of the bus cycle.

I’m not 100 percent sure, but I think at the end of a bus cycle the IIgs is immediately reversing the direction of its 74HCT245. Previously this chip was taking the peripheral card’s data from the peripheral slot data bus and moving it to an internal data bus, but now it begins taking data from the internal data bus and moving it to the peripheral slot data bus. And what data is that? In the first tens of nanoseconds after the direction is reversed, it’s actually the same data that the peripheral card was outputting, now briefly stored in the bus capacitance of the internal data bus.

What happens if the peripheral card’s output driver is a bit slow to turn off at the end of a bus cycle, due to propagation delays on the control signals? Since the peripheral card and the 74HCT245 from the IIgs are both driving the same data onto the bus, normally it should be OK. But for Yellowstone and its 3.3V 74LVC245, it’s not OK. For a time of roughly 15 ns, it causes 5V and 3.3V sources to both try to drive the bus at the same time, resulting in high current flows into the 3.3V supply, and overall badness. This is what I strongly suspect is causing Yellowstone’s end-of-cycle spikes and glitching.

There are several possible solutions:

- adjust Yellowstone’s ‘245 turn-off so it happens earlier, before the bus cycle is theoretically over

- modify Yellowstone to use a true 5V output driver, so there’s no 3.3V-to-5V conflict

- insert series resistors on the data bus to limit the current from 3.3V-to-5V conflict to safe levels

I implemented option 1, and it substantially reduced the spikes at the end of bus cycles. Surprisingly, it didn’t eliminate them completely. It feels strange to disable the ‘245 before the bus cycle is over, because the CPU doesn’t capture the bus value until the very end of the cycle. It seems like it should cause bad data to be read, causing malfunctions. But in practice it appears to work OK, probably thanks to that bus capacitance persisting the data value even after the ‘245 shuts off.

I also implemented option 2, through a bit of board surgery in which I replaced Yellowstone’s 74LVC245 with a dual-supply 74LVC8T245. This almost completely eliminated the spikes at the end of bus cycles, because the voltage on the bus stays constant at 5V after the cycle ends.

I would like to try option 3, but that will take more effort to set up.

High Current During Bus Cycles?

The second problem is the one I was chasing initially: spikes and glitches during a bus cycle, at the moment when the 74LVC245 is enabled and begins driving the data bus. I had a theory this was caused by a brief violation of the max output voltage spec of the 74LVC245, when it tries to output 3.3V but finds the bus capacitance is already charged to 5V. So I desoldered the 74LVC245 and replaced it with a 74LVT245, a nearly identical chip but with a higher max output voltage spec above 5V. Unfortunately this did nothing to help the spikes and glitches during bus cycles. Then I replaced the 74LVT245 with a 74LVC8T245, a dual-voltage chip with true 5V I/O on the Apple II side. Again this did nothing to solve the problems during bus cycles.

Based on these two tests, I concluded that violating the max output voltage spec of the 74LVC245 was never a problem, or at least it was never the main problem. The signal spikes are very likely caused by a large amount of current briefly flowing when all the data bus outputs change simultaneously from 1 to 0 or vice-versa. This is a “normal” condition, not a violation, but it’s troublesome. I’ve attempted several board modifications to help meet this sudden current demand, including adding a 10 uF bypass capacitor to the ‘245, and adding extra power and ground wires from the ‘245 straight back to the voltage regulator. None of it seemed to help.

I can’t quite explain this, since I didn’t think there should really be all that much current flowing. I guess I was wrong. But the only solution seems to be finding ways to reduce the current, or spread it out over a longer period of time. That’s what my 10101010 pre-driving trick accomplishes, but there’s plenty more room for reducing the current further.

Some possible options here:

- replace the 74LVC245 bidirectional buffer with two unidirectional buffers: an LVC buffer for input and an LS buffer for output

- insert series resistors on the data bus to limit the current

- something else I’m overlooking

The 74LS245 is an appealing option because the LS family just can’t drive very hard, at least not when outputting a high voltage. But it won’t work as a bidirectional substitute for the 74LVC245, because its 5V outputs (or close enough to 5V) would damage the FPGA. So I’d need to use the LS chip for output only, and use an LVC chip for input. That’s not very appealing. I’m also not sure how well it would reduce the current when driving low voltages instead of high ones. It might still draw too much current, or it might be fine. Isn’t this basically how all 1980s vintage peripheral cards worked? How did they avoid this problem?

Options 1 and 2 should both resolve the problems at the end of the bus cycle too, so that’s good. The other alternatives have more limited application. Adjusting the ‘245 turn-off timing does nothing to help the problems during the bus cycle, nor does using a 74LVC8T245 chip.

Unsolved Mysteries

Sadly none of the above can explain why these same problems didn’t appear in revision 1 of Yellowstone. Probably they did, but they weren’t severe enough to cause bit flips and malfunctions, so I never noticed. The only partial explanation I can think of is that revision 2’s RAM chip is to blame. Revision 1 used internal FPGA RAM and didn’t have a separate RAM chip. My guess is that the extra current used by the RAM is exacerbating the problem somehow.

Next Steps?

If you’re still reading this wall of text, it’s time to evaluate the possible solutions and make a choice. Let’s start with the simplest option: do nothing (at least from a hardware standpoint). By implementing the 10101010 pre-driving trick, adjusting the ‘245 turn-off timing, and a few other small timing changes, I’ve already improved things enough to get my prototype board working.

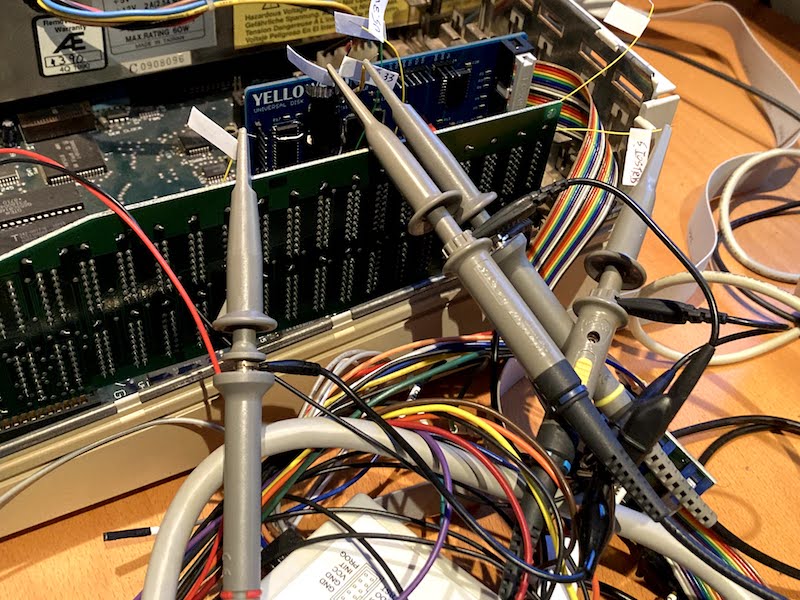

Here’s what things look like with only the FPGA logic changes. Same as in part 6, the traces shown are:

- Blue (Ch4) is address line A1. It’s a 5V input from the Apple II

- Yellow (Ch1) is the 3.3V supply voltage, measured at the VCC pin of the ‘245.

- Cyan (Ch2) is IOSTROBE, and marks the boundaries of the bus cycle.

I didn’t capture GND this time.

Yeah it still doesn’t look great, but it works. If you’ve forgotten how bad everything looked before I made the FPGA logic changes, here’s the headline image again from part 6:

So maybe this is good enough now, without needing further hardware changes? Especially if some of the ringing shown in the scope traces is due to my poor probe setup rather than being a true representation of the signal?

If a hardware change is needed, series resistors are attractive because they’re simple and easy. But what value of resistor? It must be big enough to significantly limit the current in a bus-fighting scenario, but not so big that it results in failure to meet the Vil and Vih specs of the other chips on the data bus that are receiving data.

Let’s say I used 100 ohm series resistors. In a 3.3V-to-5V bus fighting scenario at the end of a bus cycle, that would limit the current to 1.7 / 100 = 17 mA per data bus line, or 136 mA total. That’s still pretty high. Too high, I think.

If I used 500 ohm resistors, it would limit the total current to a much more modest 27.2 mA total, but it would create a new problem. For the 74LS family inputs on the data bus of the Apple IIe, and for as many as six other peripheral cards installed that use 74LS parts, the inputs source 0.2 mA when they’re “receiving” a logical low value. All combined that’s 1.4 mA worst case. With 500 ohm resistors and a current of 1.4 mA, even if Yellowstone could output a true 0.0V logical low value, the LS inputs would see a voltage of 1.4 * 500 = 0.7V, which is almost above the Vil threshold for 74LS family parts. In short, with a fully loaded set of 7 peripheral cards that all use 74LS logic, and 500 ohm resistors, Yellowstone might not work.

There’s some middle ground here. Resistor values from roughly 150 to 500 could probably work to solve both problems, but it’s a narrow enough range that it makes me slightly nervous. Maybe go with 220 or 330 ohm.

If a hardware change is needed but series resistors won’t do, then I think the only viable alternative is a two-chip solution with 74LS output and 74LVC input. But I don’t love this solution, for the reasons mentioned previously: extra chips, extra design complexity, and a concern it might not work anyway for driving a logical low voltage. There would be a small amount of additional control complexity too. Each chip would need a separate enable signal from the FPGA, where spare pins are scarce, and extra care would be needed to prevent enabling both at once.

Some other combination of solutions might be possible too, like 74LVC8T245 with series resistors. But I don’t want to go overboard.

As you might expect, I’ve grown very tired of this glitching problem, and my enthusiasm for further tests and experiments is low. My gut says to accept the software-only solution and call it good, or else maybe to add series resistors. But I don’t want to sweep this problem under the rug, only to have it reappear later in rare circumstances I can’t troubleshoot. If you were me, what would you do?